In order to meet a wide range of needs, we supply everything from materials to processed goods and devices for the electric and electronics and semiconductor industries, where continuing development in the future is expected. In addition, we tied up with our Taipei branch, Shanghai office, and overseas partners to actively take on the development of new products, fields, and other activities in order to expand and evolve our business in the burgeoning regions of South Korea, Taiwan, China, and Southeast Asia.

- Battery materials

-

Lithium-ion battery materials [positive-electrode materials, negative-electrode materials, electrode tape, binders, and additives]

Materials for primary batteries and capacitors

Electrolyte material [LiPF6, LiBF4, various solvents: PC, EC, DMC, and DEC]

Evaluation test device [3-electrode cell,battery testing systems, battery can for testing, and manufacturing and experiment facilities (bead mill)]

- Carbon product and consumable parts in vacuum furnace

-

Heat insulating materials for high-temperature vacuum furnaces [carbon fiber molded insulation material FR]

Carbon fiber [chop, felt, cloth, yarn, paper, and veil mats]

Beard-shaped activated carbon [BAC]

Carbon heater, alumina processed product, zirconia crucible, and processed products from high-melting metals, such as Ta and Mo

C/C composite base trays for vacuum heat-treatment furnaces and C/C composites for vacuum heat-treatment furnaces

Alumina jigs for optical lens manufacturing equipment

- High-performance film

-

KFC film [PVDF co-extruded multilayer film]

CELLEL [super moisture-barrier film]

- Electronics materials

-

Piezo film [piezoelectric polymer PVDF film]

Piezo sensor [low-profile piezoelectric sensor]

Ultrasonic probe [for wideband use]

Encoder [low-profile magnetic encoder]

- High-functional resin

- Engineering plastics in general

- Kureha Microsphere [Thermally expandable microcapsule]

- Hollow sphere pigment for coated paper and ink

- Antistatic materials

-

ESD control materials [Krefine]

-

- Control of resistance value by ±1-th power

- To be used for ESD measures for semiconductors and HD manufacturing processes

- Pellets for injection molding and extruded plate materials for cutting processing

- Inorganic materials/heat dissipation materials/metal powder

- Barium titanate (BT)

- Yttria-stabilized zirconia (YSZ)

- Aluminum nitride (AlN) heat dissipation substrate, filler, etc.

- Setter for boron nitride (BN) sintered objects

- Flaky magnetic powder

(1) High-aspect ratio magnetic flake powder, (2) Highly soft magnetic, (3) Uniform particle size

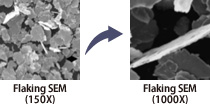

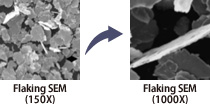

- Mill for grinding and dispersion [Dry & wet type bead mills]

- Technical support for customers who require particles down to nano and submicron size

- Supplying of bead mills for laboratory and industrial uses

- Laboratory tests and toll grinding

Disperser of mass production for nano scale

(Wet type bead mills)

Continuous dry type bead mills

for laboratory

* Photo provided by Kureha Corporation

* Photo provided by Kureha Corporation